Product features

Product's features

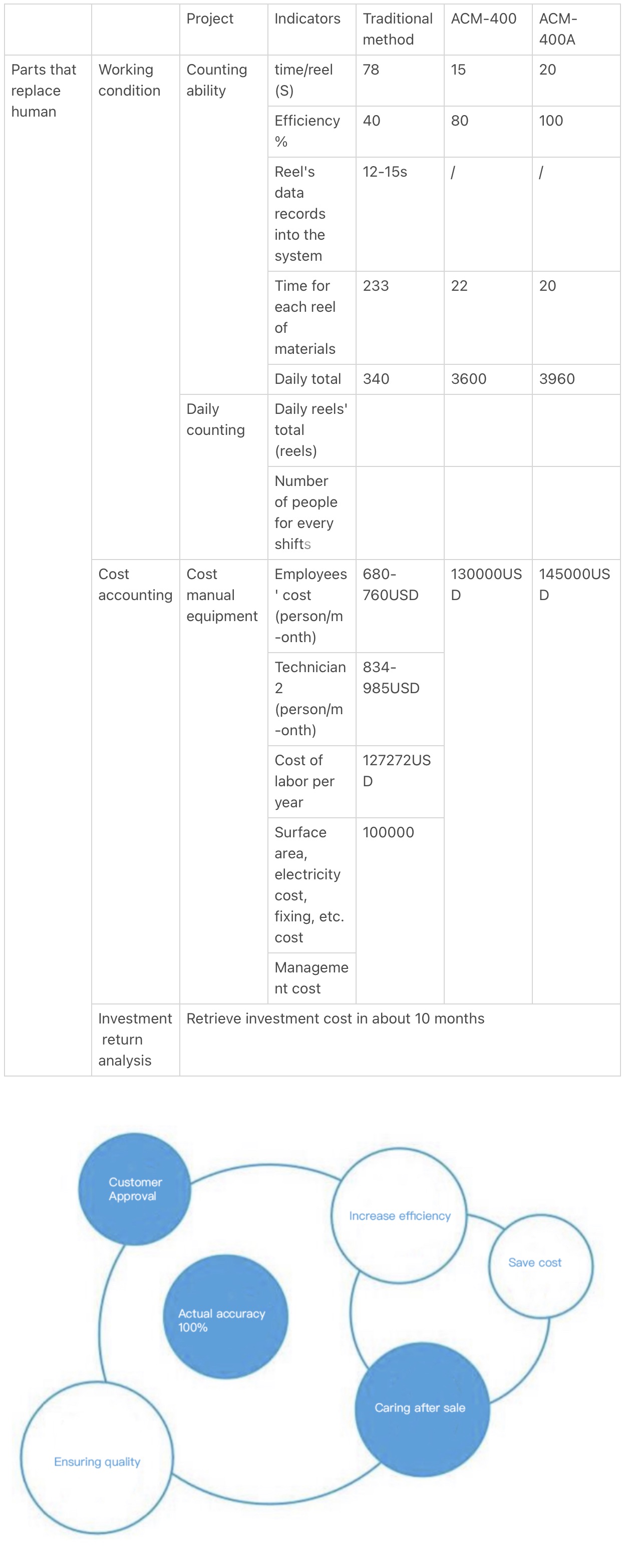

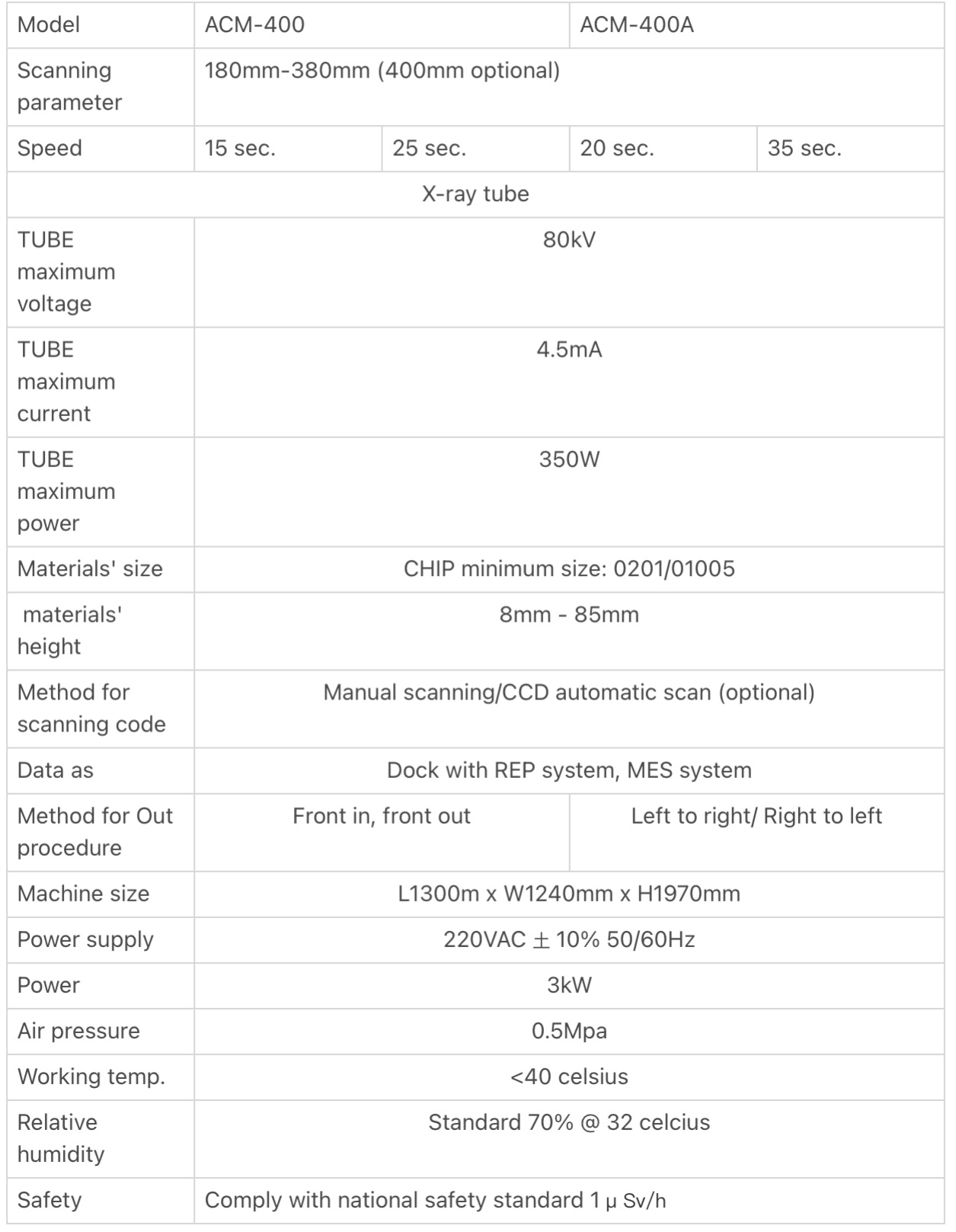

SMT full-auto materials counting system is also known as automatic parts counting machine, SMT automatic parts counting machine, SMT counter, parts counting machine and many other names, is produced by Shenzhen Bluiris Technology Co, here is its basic specification:

1.Performace index

Pan size: small diameter: 180mm; large diameter: 380mm

Single inlet and outlet/left inlet and outlet; Single inlet and outlet/right inlet and outlet(dual-use)

Front pallet/rear robotic

Counting accuracy:99.9%;

Counting speed (single in single out): 180MM-about 16 seconds; 330MM-about 23 seconds; 380MM-about 29 seconds

Working voltage:AC110~220V 15A 50/60HZ;

Low radiation<1μSv/h

Automatic scanning barcode; able to print barcode or on-board system connected to ERP/MES system

2.Counting device's composition

Anti-leakage shielding shell: using high-density lead version leakage<1uSv/h

X-ray tube

X-ray PDF: X-ray conversion of visible images

Equipment operating system: mechanical motion control part

Software algorithm: Software automatically process the image and get the result.

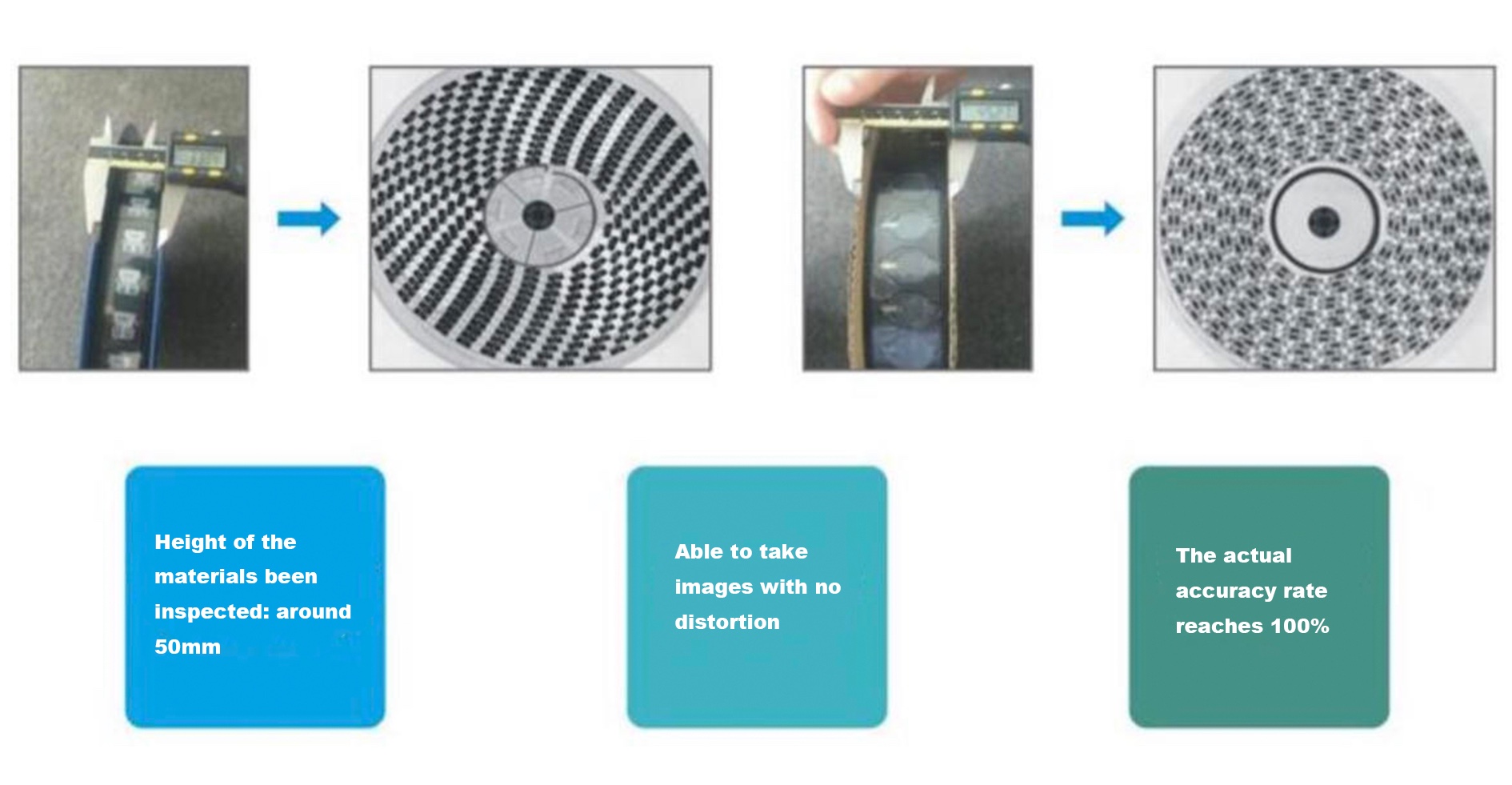

Range of application for materials with high heights

The equipment can check about 50mm height material, currently can reach the market requirements. The image taken will not have distortion

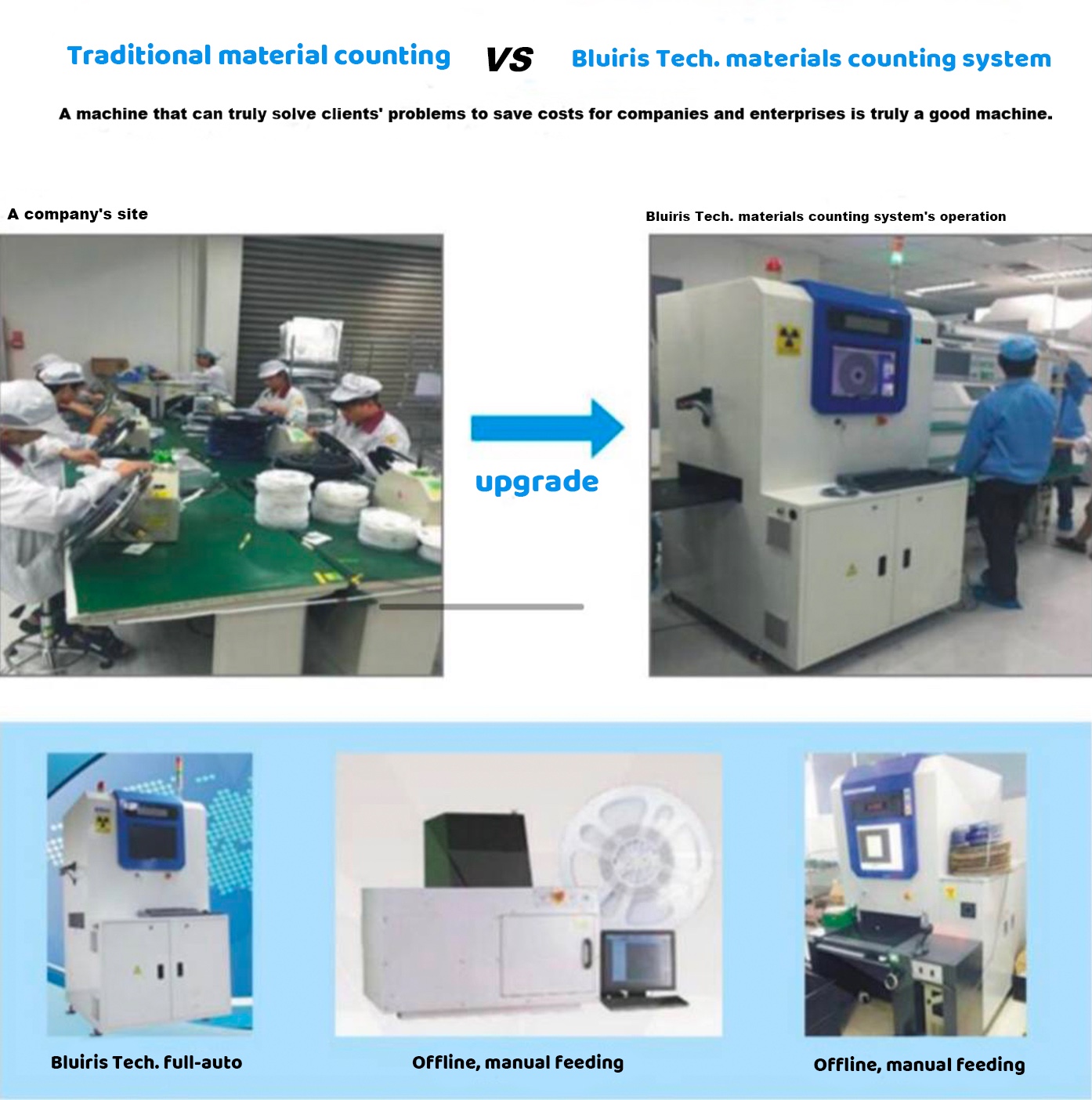

Advantage of the full-auto counting machine

1.Counting speed:20 seconds/reel

2. Online inspection, no manual process

3. Replace 4-8 people

4. Improve the accuracy of storage materials

5. Automatic scanning and printing barcode

Producer: BLUIRIS

Name: Automatic Material Counting System

Description: fully automatic, one machine to replace 10 people, calculation accuracy reaches 99.9%

Features: Improve efficiency and save cost

Consult: TEL: 0755-86149022

Official Account

Official Account